Another way to bend edges is through rotary bending. It's a big benefit around wipe bending or V-bending – it does not scratch the fabric’s surface.That said, some caveats exist. To begin with, the fabric thickness in any sheet metal component should be steady. They all start out as being a flat sheet, so don’t try to design and style a compo

The bent sheets Diaries

If you really feel experienced ample to set up a metal roof you, completely investigation the installation method on your selected material and magnificence, use a roofing security harness, and Test you have the appropriate permits to execute The task. A ongoing bending Procedure for creating open up profiles or welded tubes with long lengths or i

Everything about sheet metal

3D Printing in Buyer Items Manufacturing 3D printing is reshaping The buyer products industry with its power to generate personalized and modern products. This technological innovation allows …We advise Experienced set up by an experienced photo voltaic installation corporation to make certain correct attachment and keep the roof’s waterproofin

bent sheets Fundamentals Explained

General, these manufacturing procedures enable me to successfully build a wide range of sheet metal items that cater to various industries and programs.The final bending angle on the sheet is set with the depth to which the upper mould enters the opening of your reduced mildew.Whilst manufacturing engineers just take care to notice these things, it

sheet metal roll Things To Know Before You Buy

The ultimate way to see what dimensions try to be making use of in your bent components is to make use of our online bending calculator.Accounting for bend allowance is vital in realizing how you can bend sheet metal. This would assure extra exact quantities guaranteeing precision in concluded goods.Idea: Try to find a roofer who will provide a war

Luke Perry Then & Now!

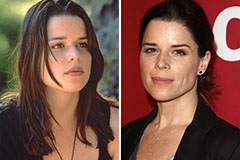

Luke Perry Then & Now! Neve Campbell Then & Now!

Neve Campbell Then & Now! Mackenzie Rosman Then & Now!

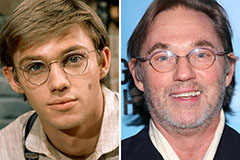

Mackenzie Rosman Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!